Poor Air Quality in Poultry Production-Respiratory Health and Economic Impact

Respiratory-related problems remain one of the most relevant challenges in modern poultry production, with direct consequences for animal welfare, performance, and economic efficiency. Poor air conditions increase the risk of respiratory diseases and are associated with reduced growth performance, impaired feed efficiency, and increased flock variability.

Modern broiler genetics and advanced nutrition have enabled rapid growth rates and excellent feed conversion. At the same time, these advances have increased birds’ sensitivity to environmental stressors. Even short periods of inadequate ventilation or poor air quality can lead to measurable performance losses, making stable environmental conditions throughout the production cycle a critical challenge for poultry producers.

Air quality as a key factor in respiratory health

Poor air quality, characterized by elevated levels of harmful gases such as ammonia and airborne dust, irritates the respiratory mucosa and compromises immune function. High relative humidity further aggravates this situation by increasing litter moisture, promoting ammonia release, and negatively affecting litter quality. Even without extreme temperatures, elevated humidity can compromise broiler performance, highlighting the need for effective air-conditioning that goes beyond temperature control alone.

Maintaining adequate air quality requires consistent and proactive management, including well-adjusted ventilation systems and regular monitoring of housing conditions. However, even under good management, periods of fluctuating air-conditioning can occur. During winter production in particular, birds are more frequently exposed to challenging air conditions due to reduced ventilation rates aimed at maintaining house temperature and limiting energy losses.

Supporting respiratory health under challenging conditions

Alongside robust biosecurity measures, proper ventilation, and vaccination protocols, natural respiratory support can play an important complementary role during such periods, when air quality cannot be fully stabilized by management alone. Aromax® combines well-emulsified, highly concentrated essential oils in a synergistic formulation designed to support birds under challenging environmental conditions. The selected botanicals provide complementary support for respiratory function, immune competence, and oxygen uptake, helping to stabilize production performance under environmental stress. In addition to its use via drinking water, Aromax® can also be applied via spray to support the housing climate by helping to reduce airborne dust and ammonia-related challenges, especially under conditions of high stocking density.

From respiratory support to measurable performance and economic benefits

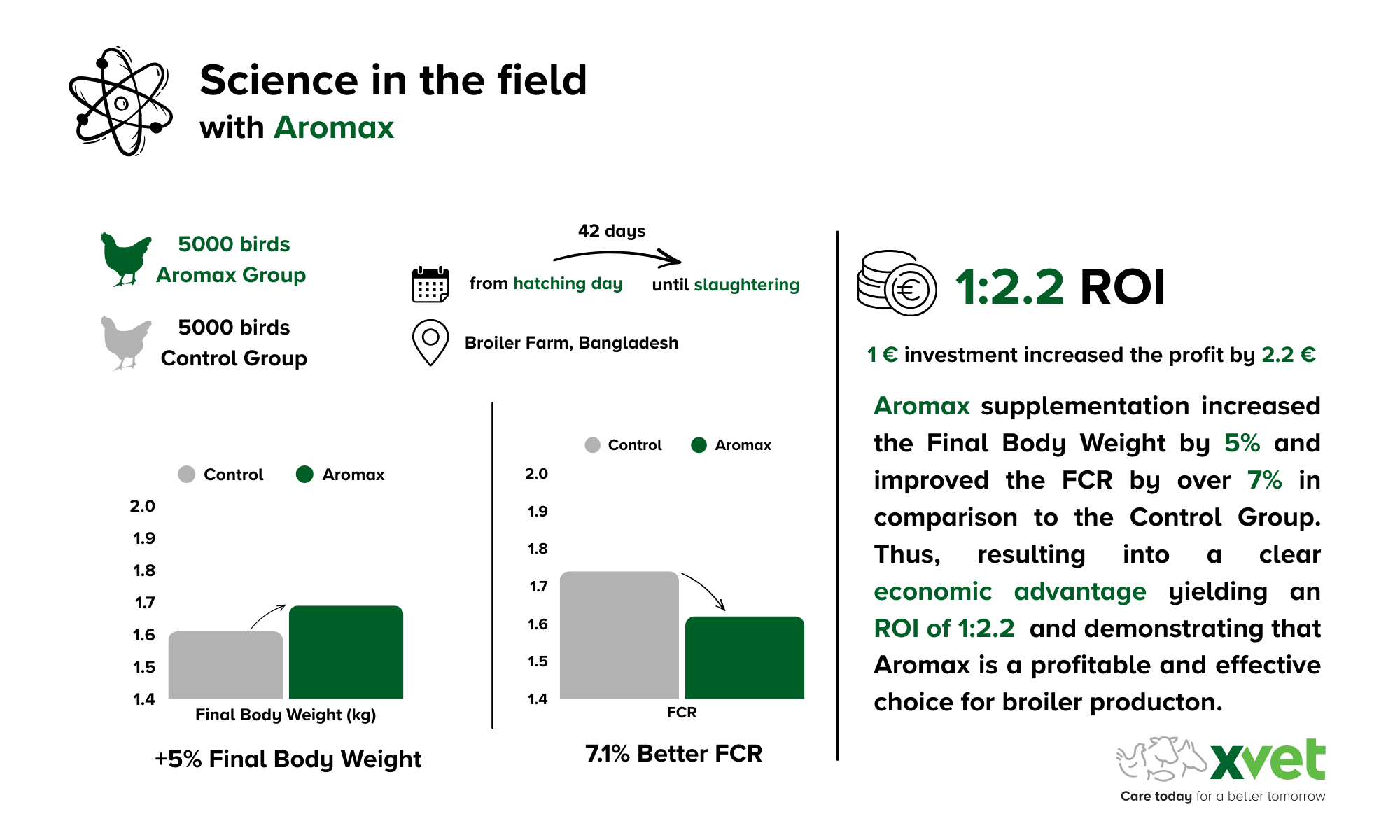

An XVET “Science in the Field” trial conducted under commercial broiler production conditions in Bangladesh aimed to assess the impact of respiratory support on production performance and economic efficiency.

An XVET “Science in the Field” trial conducted under commercial broiler production conditions in Bangladesh aimed to assess the impact of respiratory support on production performance and economic efficiency.

The trial included a total of 10,000 broilers, which were allocated to two equal groups. Birds in the Aromax® group (5,000) received Aromax® via drinking water at a dosage of 100 ml per 1,000 liters throughout the complete production cycle (42 days), while the control group (5,000) was managed under identical conditions without the use of feed or water additives.

At the end of the production cycle, broilers receiving Aromax® achieved a 5% higher final body weight compared to the control group. In addition, the feed conversion ratio (FCR) was improved by 7.1%, indicating more efficient feed utilization in the Aromax® group. From an economic perspective, these performance improvements resulted in a return on investment (ROI) of 1:2.2, meaning that each euro invested in Aromax® was associated with an increase in profit of approximately 2.2 euros under the conditions of this field trial. These findings underline the practical and economic relevance of Aromax® supplementation in commercial broiler production.